In the largest intelligent logistics hub in Asia, within the 24-meter-high three-dimensional warehouses, automatic guided vehicles shuttle like a swarm of bees, stacker cranes precisely store and retrieve goods at a speed of 6 meters per second, and the sorting system processes 200,000 packages per hour - the level of automation in modern warehousing has reached an astonishing height. However, behind this efficient operation, any failure at a control node could lead to the paralysis of the entire logistics system, causing economic losses of hundreds of thousands of yuan per hour and disruptions to the supply chain.

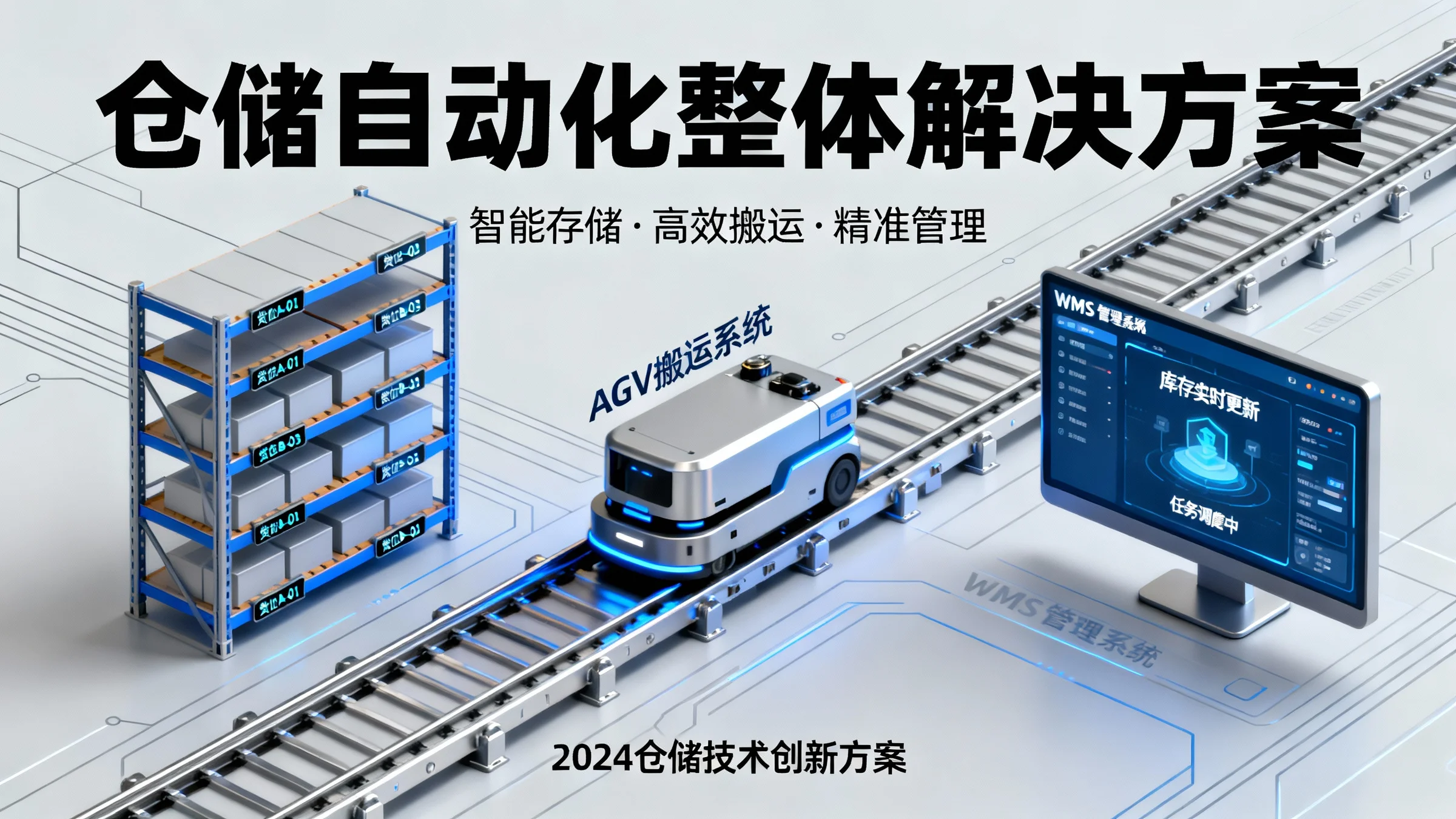

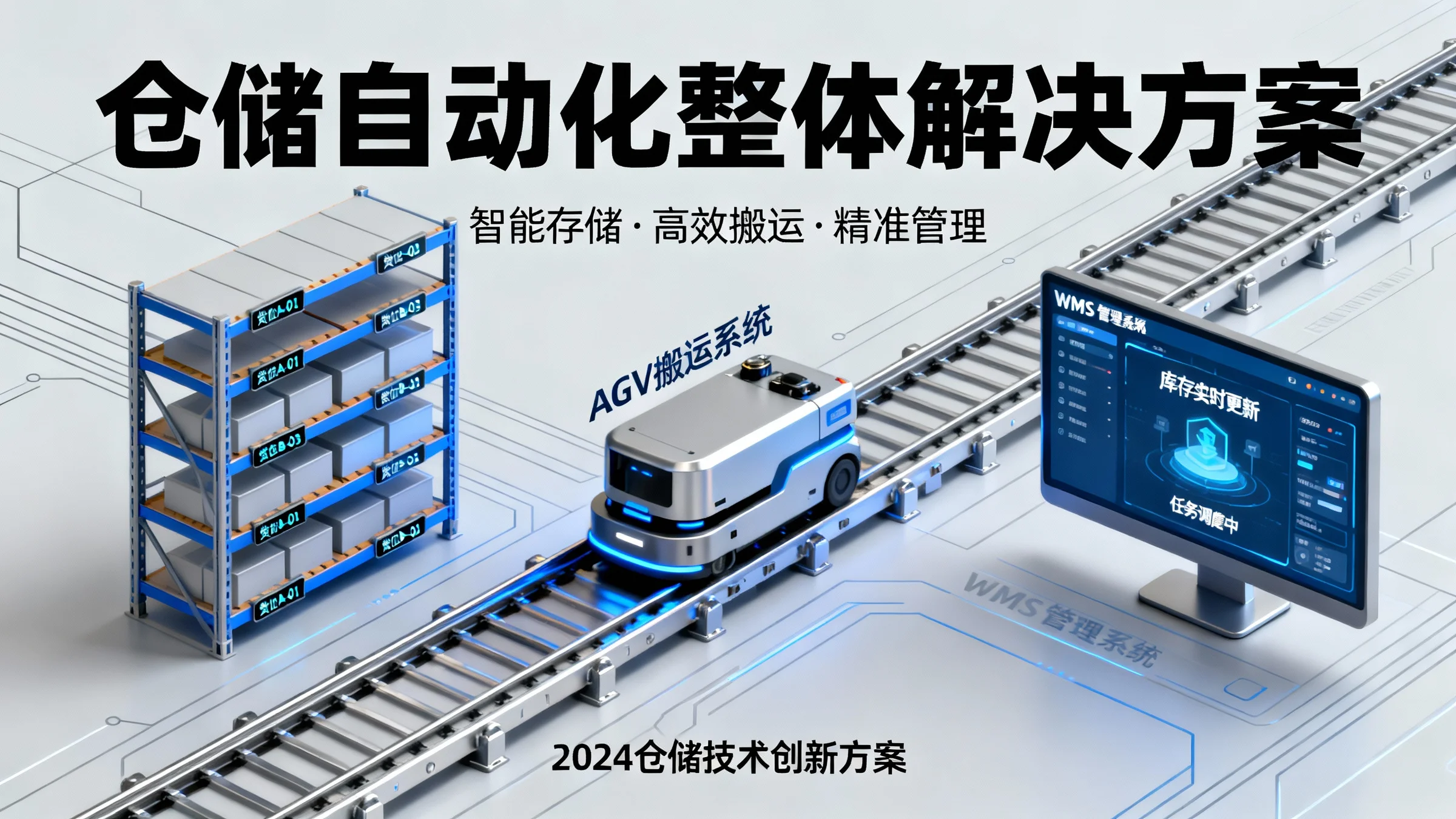

Based on its profound accumulation in the field of industrial automation, Godel Electric has developed a full range of solid-state relay solutions specifically for logistics, catering to the unique demands of automated warehousing. These solutions provide reliable, efficient and intelligent power control guarantees for every link in the modern logistics system, from inbound to outbound.

Stereoscopic Warehouse: Precise Control of High-altitude Operations

The height and density of modern stereoscopic warehouses are constantly increasing, which poses extremely high requirements for the control of stacker cranes:

Stacker crane control system:

High-speed positioning control: Horizontal speed 6m/s, vertical speed 2.5m/s, positioning accuracy ±2mm.

Double-deep access control: Precise access to the second row of storage locations, with position repeatability accuracy of ±1mm.

Loading platform control: Fork extension and retraction speed 0.5m/s, positioning accuracy ±1mm.

Safety protection control: Multiple anti-collision, anti-drop, and anti-over-limit safety protection.

Shelf and Conveying System:

Shelf detection control: Dual detection by laser and vision, with the accuracy rate of shelf status recognition over 99.9%

Conveyor line synchronous control: Synchronous speed control of multiple conveyor sections, with a synchronization error of less than 0.5%.

Accumulation and release control: Intelligent accumulation and release system, optimized buffer zone utilization

Maintenance passage control: Automatic control of the opening and closing of the maintenance passage

Environmental Adaptation Design:

Temperature Adaptation: Wide temperature operation range from -10℃ to +55℃, suitable for warehouses in different climate zones.

Dust protection: IP65 protection grade, resistant to dust in storage environments.

Seismic design: The stable working capacity of the shelves under slight shaking

Long-term operation: 24×7 continuous operation, designed service life of over 10 years.

At JD Asia No.1 Intelligent Warehouse, the Godel stacker crane control system has achieved a 99.98% equipment availability rate, increased storage density by 40%, and improved inbound and outbound efficiency by 50%.

Sorting System: High-speed and Precise Logistics Distribution

The requirements for processing speed and accuracy at express sorting centers are increasing day by day:

Cross-belt sorter control:

High-speed sorting control: Sorting speed 3m/s, sorting efficiency 20,000 pieces per hour.

Precise grid drop control: The accuracy of the package's drop position is ±30mm.

Dynamic weighing control: Weighing during movement, with a weight accuracy of ±10g.

Barcode recognition control: Multi-angle reading, recognition rate > 99.5%

Swing wheel sorting system:

Direction control: Response time for pendulum wheel steering < 50 ms

Spacing adjustment: Automatically adjust the spacing of the rollers according to the size of the package.

Speed matching: Precisely match the main line speed, with speed error < 2%

Blockage detection: Real-time blockage detection and automatic processing

Slider sorting control:

Matrix control: Large-scale slider matrix collaborative control

Path Planning: Intelligent Path Planning Based on Destination

Traffic balancing: Multi-exit traffic balancing control

Exception handling: Automatic rejection and processing of abnormal packages

Robot sorting system:

Parallel robot control: Delta robot high-speed grasping, cycle time < 1 second

Mobile robot sorting: AMR collaborative sorting, dynamic path optimization

Visual guidance control: Target recognition and localization based on deep learning

Human-robot collaborative control: Safe collaborative operation between humans and robots

After adopting the Godel control system, the Shunfeng South China Sorting Center has reduced its sorting error rate from 0.05% to 0.005%, increased its peak processing capacity by 35%, and cut its labor costs by 60%.

Automated Guided Vehicle (AGV) System: The Intelligent Carrier of Flexible Logistics

The intelligence level of the AGV system determines the flexibility of the warehouse:

Navigation and Positioning Control:

Laser SLAM navigation: Positioning accuracy ±10mm, mapping accuracy ±30mm

QR code navigation: Recognition speed 3m/s, recognition rate > 99.9%

Inertial navigation assistance: dead reckoning during brief signal loss

Multi-sensor fusion: Positioning based on the integration of multi-source data from laser, vision, and IMU.

Motion control:

Differential drive control: Steering accuracy ±1°, straight-line accuracy ±20mm/m

Omni-directional movement control: Mecanum wheels enable omni-directional movement, enhancing flexibility.

Speed planning: Intelligent speed planning based on the path, saving 15% of energy.

Vibration control: Smooth operation control on uneven roads

Task Scheduling and Coordination:

Multi-vehicle dispatching: Coordinated dispatching of over 200 AGVs with conflict-free path planning

Dynamic priority: Dynamic priority adjustment based on the urgency of tasks

Traffic management: Virtual traffic signal control, optimization of intersection passage efficiency

Charging Scheduling: Intelligent charging scheduling to keep the fleet in optimal condition.

Safety protection:

Three-level anti-collision: laser, ultrasonic, and bumper three-level anti-collision protection

Emergency stop: Quick and safe stop in emergency situations

Regional management: Electronic fence management for hazardous areas and speed-limited areas

Status Monitoring: Real-time status monitoring and anomaly early warning

The 800 AGVs deployed in the Cainiao Wuxi Future Park are equipped with the Godel control system, achieving a task completion rate of 99.5%, reducing the average waiting time by 40%, and enhancing the overall operational efficiency by 55%.

Cold chain warehousing: Reliable control in low-temperature environments

Cold chain logistics has special requirements for temperature control and equipment reliability:

Precise temperature control:

Multi-temperature zone control: Independent and precise control of multiple temperature zones from -25℃ to +15℃.

Temperature uniformity: ±1℃ temperature uniformity within the warehouse, hot spot elimination

Humidity control: Maintain relative humidity at 85% to 95% to prevent dry loss.

Temperature traceability: Full temperature recording and traceability throughout the process, in compliance with FDA requirements.

Refrigeration equipment control:

Refrigeration unit control: Intelligent control of variable frequency compressors, saving 25% energy.

Cold air fan control: Optimized defrosting cycle, improved defrosting efficiency

Air curtain control: Intelligent start and stop of the air curtain at the warehouse door reduces cold loss.

Emergency system: Automatic switching between dual power supplies, power failure protection

Low-temperature Adaptation of Automated Equipment:

Low-temperature stacker crane: Normal operation in -25℃ environment, specially designed lubrication system

Cold chain AGV: Low-temperature battery management, maintaining endurance capacity

Anti-condensation design for conveyor lines: Prevents condensation and ice formation to avoid slipping.

Electronic device protection: low-temperature startup, anti-condensation, and anti-ice crystal design

Quality maintenance control:

Gas regulation: Precise control of oxygen and carbon dioxide concentrations

Ethylene removal: Control of ethylene removal system, extended shelf life

Ice temperature control: -0.5℃ to 0℃ ice temperature preservation control

Vacuum cooling: Vacuum pre-cooling control for fruits and vegetables, reducing pre-cooling time by 50%

At Yonghui Superstores' cold chain logistics center, the Godel control system has enabled temperature control accuracy of ±0.5℃, reduced the cold chain breakage rate to below 0.01%, and lowered the commodity loss rate by 2.5 percentage points.

Specialized Warehouse Environment Adaptation Technology

The diversity of warehouse environments requires control equipment to have wide adaptability:

Explosion-proof environment application:

Chemical warehouse control: Explosion-proof grade Ex d IIB T4, suitable for hazardous materials storage.

Dust explosion-proof control: Dust explosion-proof design, suitable for grain and feed storage.

Gas detection interlock: Combustible gas detection and ventilation system interlock

Intrinsic safety design: Automatically enter a safe state in case of failure.

Clean environment control:

Dust-free room storage: Class 1000 cleanliness maintained, static protection

Pharmaceutical warehouse control: GMP compliance control, precise temperature and humidity management

Electronic raw material storage: ESD protection, cleanliness maintenance

Food clean storage: Hygienic grade design, easy-to-clean surface

Heavy-duty warehouse control:

Automotive parts warehousing: Heavy-duty shelving and stacker crane control

Steel storage control: Precise control of cranes and lifting gear

Mold storage control: Heavy mold access control

Special equipment storage: Control of special storage equipment for irregular-shaped parts

Special materials storage:

Comprehensive control of isolation, ventilation and leakage detection for hazardous chemicals storage

Precious Metal Storage: Integration of Multiple Security and Monitoring Systems

Document and archive storage: Temperature and humidity control for pest and mold prevention

Emergency Materials Warehousing: Rapid Response and Outbound Control

Intelligent Management System Integration

Gordon offers an overall solution for warehouse automation:

WMS/WCS Integration:

Seamless integration: Connect with mainstream WMS systems through standard interfaces

Task Optimization: Task Optimization Scheduling Based on WMS Orders

Inventory synchronization: Real-time inventory data synchronization with an error rate of less than 0.1%.

Exception handling: Automatic processing and reporting of abnormal situations

Digital twin system:

Three-dimensional visualization: Real-time three-dimensional visualization of warehouse equipment and operations

Simulation Optimization: Layout and Process Optimization Based on Digital Twinning

Predictive analysis: Workload prediction, equipment load prediction

Virtual commissioning: Virtual debugging and verification before the new system goes online

Data Analysis and Optimization:

Efficiency analysis: Multi-dimensional analysis of equipment efficiency and personnel efficiency

Bottleneck identification: Identification of bottlenecks in the operation process and optimization suggestions

Cost Analysis: Job Cost Analysis and Optimization

KPI Monitoring: Real-time Monitoring of Key Performance Indicators

Predictive maintenance:

Health Monitoring: Real-time Monitoring of the Health Status of Key Equipment

Fault prediction: Early fault prediction based on equipment data

Maintenance Optimization: Optimization of Condition-Based Maintenance Strategies

Spare parts management: intelligent spare parts demand forecasting and inventory management

Economic Benefits and Industry Value

The Gordon Smart Warehouse Solution creates significant value:

Improvement in operational efficiency:

Storage density increase: The storage density of three-dimensional warehouses increases by 2 to 4 times.

Work efficiency improvement: Inbound and outbound efficiency increased by 50-100%

Accuracy improvement: Inventory accuracy > 99.9%, sorting accuracy > 99.5%

Space utilization rate: Warehouse space utilization rate increases by 30-50%

Cost savings are obvious:

Labor cost: Automation reduces labor by 60-80%

Energy consumption savings: Intelligent control saves 15-25% of energy.

Loss reduction: 30-50% reduction in product loss

Land cost: Land demand for the same storage capacity is reduced by 50-70%.

Service quality improvement:

Order Response: Order processing time reduced by 50-70%

On-time delivery: On-time delivery rate > 99.5%

Traceability: Full-process traceability to meet customer requirements.

Flexibility: Enhanced ability to adapt to promotions and peak seasons.

Investment return analysis:

New automated warehouse: Payback period of 3 to 4 years, internal rate of return of 25% to 35%

Traditional warehouse renovation: Payback period of 2-3 years, internal rate of return of 30-45%

Cold chain warehousing project: Payback period of 4 to 5 years, internal rate of return of 20% to 30%

Special warehousing project: Payback period 3-5 years, internal rate of return 18-28%

Future Trends and Technological Development

Smart warehousing technology is developing rapidly:

Evolution of Robotics Technology:

Applications of humanoid robots: The application of humanoid robots in warehouse operations

Soft robots: Flexible grasping and manipulation robots

Swarm robots: Large-scale collaborative operations of robot swarms

Self-learning robots: Robot Skill Learning Based on Reinforcement Learning

Deepening of AI and Big Data:

Intelligent Forecasting: Demand Prediction and Inventory Optimization Based on AI

Dynamic path planning: Real-time dynamic path planning algorithm

Anomaly Detection: Anomaly Behavior Detection Based on Deep Learning

Autonomous Decision-making: Autonomous Decision-making and Optimization of Warehouse Systems

New storage technology:

Dense storage system: Automated storage systems with higher density

Air logistics: The application of drones within warehouses

Underground warehousing: Underground automated warehousing system

Mobile warehousing: A movable and reconfigurable warehousing system

Sustainable development:

Green warehousing: Energy-saving and environmentally friendly warehouse design and operation

Circulating packaging: Automated processing of recyclable packaging

Carbon-neutral warehousing: Application of renewable energy and carbon-neutral technologies

Resource sharing: The sharing and optimized utilization of warehousing resources

Against the backdrop of the rapid development of the logistics industry and the continuous growth of e-commerce, Godel Electrical will continue to focus on the field of smart warehousing. With advanced and reliable control technology, it will contribute to the development of the logistics industry towards automation, intelligence and greenness. From inbound to outbound, from storage to sorting, Godel control systems are safeguarding every key node of modern logistics.

Choosing the Godelin intelligent warehousing solution means choosing the future of logistics efficiency. Let's join hands and use innovative control technology to jointly build a more intelligent, efficient and reliable warehousing and logistics system, providing solid support for the development of new retail, new manufacturing and new logistics.