- Home

-

Products

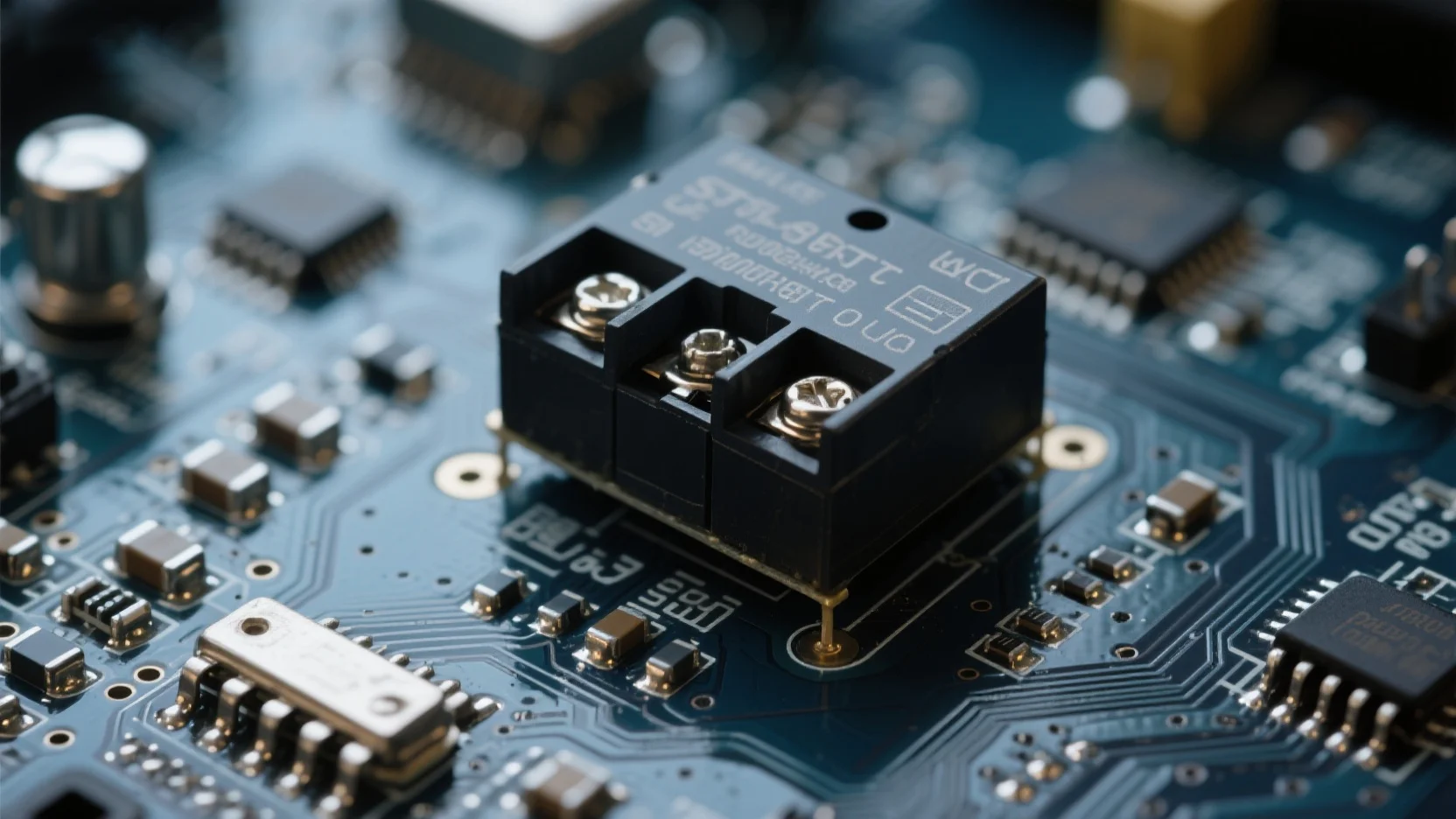

- > 1 Phase Insert Pull SSR - GSI

- > 1 Phase Flip Covers SSR - GSP-C [HOT! ]

- > 1 Phase Anti-Slip SSR - GSP

- > 1 Phase Totally Metal SSR - GSQ

- > 1 Phase Modular SSR - GSM

- > 1 Phase Strip-Shape Flip Covers SSR - GST

- > 1 Phase Heatsink Integrated SSR - GSH [HOT! ]

- > 3 Phase Flip Covers SSR - GS3 [HOT! ]

- > 3 Phase Heatsink Integrated SSR - GS3H

- > Heatsink & Accessories

-

Industries

- > New energy & solar power

- > Air Conditioning & regulator equipment

-

> Traditional industries

- Glass Tempering Furnace

- Sintering Furnace

- Ceramic Sintering Furnace

- Chemical Fiber Equipment

- Elastic Yarn Machine

- Non-woven Mask Machine

- Bag Making Machine

- Textile Printing & Dyeing Machinery

- Printing Equipment

- Packaging Equipment

- Wire Drawing Machine

- Stamping Equipment

- Industrial Electric Furnace

- Fuel Dispenser Equipment

- Mining Machinery Equipment

- Automotive Production Equipment

- Heavy-duty Vehicles

- Glass Tempering Furnace

- > Plastic machinery industry

- > Food processing & medical equipment

- > Automated, semi & intelligent industry

- > Smart Home Systems

- > Smart Warehouse

- > Intelligent Solid-state Switchgear

- About Us

- Download

- Technology

- News

-

Contact Us

-

- > 1 Phase Insert Pull SSR - GSI

- > 1 Phase Flip Covers SSR - GSP-C [HOT! ]

- > 1 Phase Anti-Slip SSR - GSP

- > 1 Phase Totally Metal SSR - GSQ

- > 1 Phase Modular SSR - GSM

- > 1 Phase Strip-Shape Flip Covers SSR - GST

- > 1 Phase Heatsink Integrated SSR - GSH [HOT! ]

- > 3 Phase Flip Covers SSR - GS3 [HOT! ]

- > 3 Phase Heatsink Integrated SSR - GS3H

- > Heatsink & Accessories

-

+1 227 241 2073

goldenssr@goldenssr.com