During the inspection process in industrial sites, a significant increase in the temperature of the power regulator's casing is a common occurrence. This could either be a sign of normal operation or a precursor to a malfunction. Accurately determining its nature is crucial for ensuring the continuity of production and the safety of the equipment.

I. Definition of Normal Heating and Abnormal Overheating

Normal heating

When the back of the hand can stay in contact with the shell for more than 5 seconds, and the surface temperature is usually between 40℃ and 60℃ (feeling similar to the wall of a thermos cup filled with hot water), such temperature rise is mostly normal. The heat mainly comes from the inherent losses of power devices such as thyristors and reactors inside during the process of electrical energy conversion, which is particularly obvious during high-power or high-load operation.

Abnormal overheating

If the hand feels a burning pain immediately upon contact and cannot stay there, it is estimated that the surface temperature exceeds 70℃ (close to the temperature of a kettle's outer shell), or if there are accompanying phenomena such as a burnt smell, shell deformation, or abnormal sounds, it is a clear fault signal. The machine must be stopped immediately and checked.

II. Systematic Analysis of the Root Causes of Heating

1. Reasonable Working Temperature Rise

Power loss: During the voltage regulation and power adjustment processes of a power regulator, the conduction and switching of semiconductor devices (such as thyristors) will generate power loss, which is dissipated in the form of heat energy. This is an inevitable physical phenomenon.

Environmental impact: Installation in a control cabinet with poor ventilation or in an environment with excessively high temperatures (such as a workshop in summer) will significantly reduce the equipment's heat dissipation efficiency, resulting in a corresponding increase in the temperature of the casing.

Abnormal overheating that indicates a fault.

Failure of the cooling system:

The cooling fan stops rotating due to dust and oil accumulation, jamming or its own malfunction.

The thermal grease between the heat sink and the power device dries up, ages or is unevenly applied, and the installation pressure is insufficient, resulting in increased thermal resistance and ineffective heat conduction.

Equipment overload or internal failure:

The actual load power continuously exceeds the rated capacity of the equipment, causing the components to overheat due to excessive stress.

Internal components (such as thyristors) experience breakdown short circuits, or control circuits malfunction, causing continuous large current heating.

Electrical connection hazards:

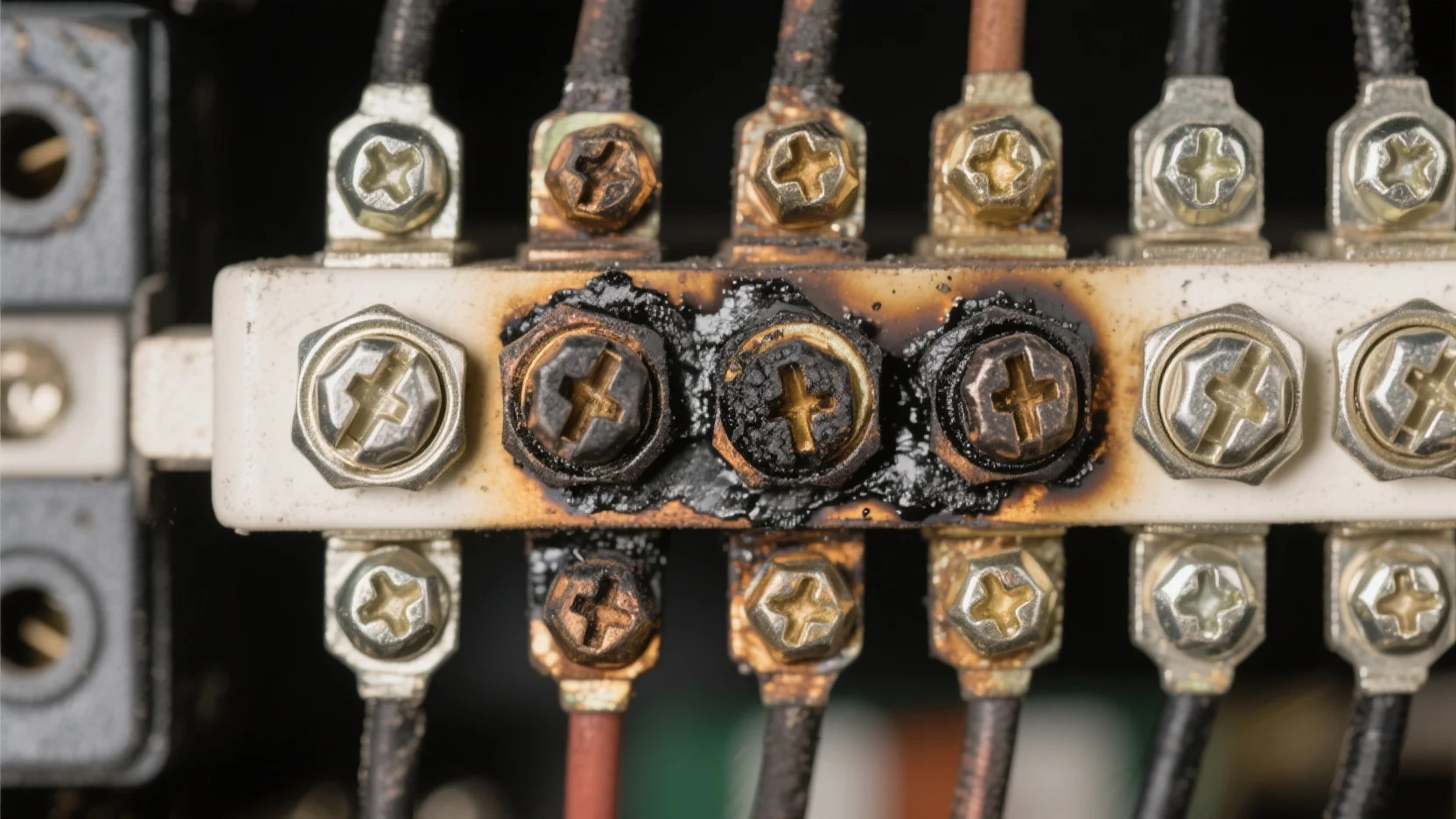

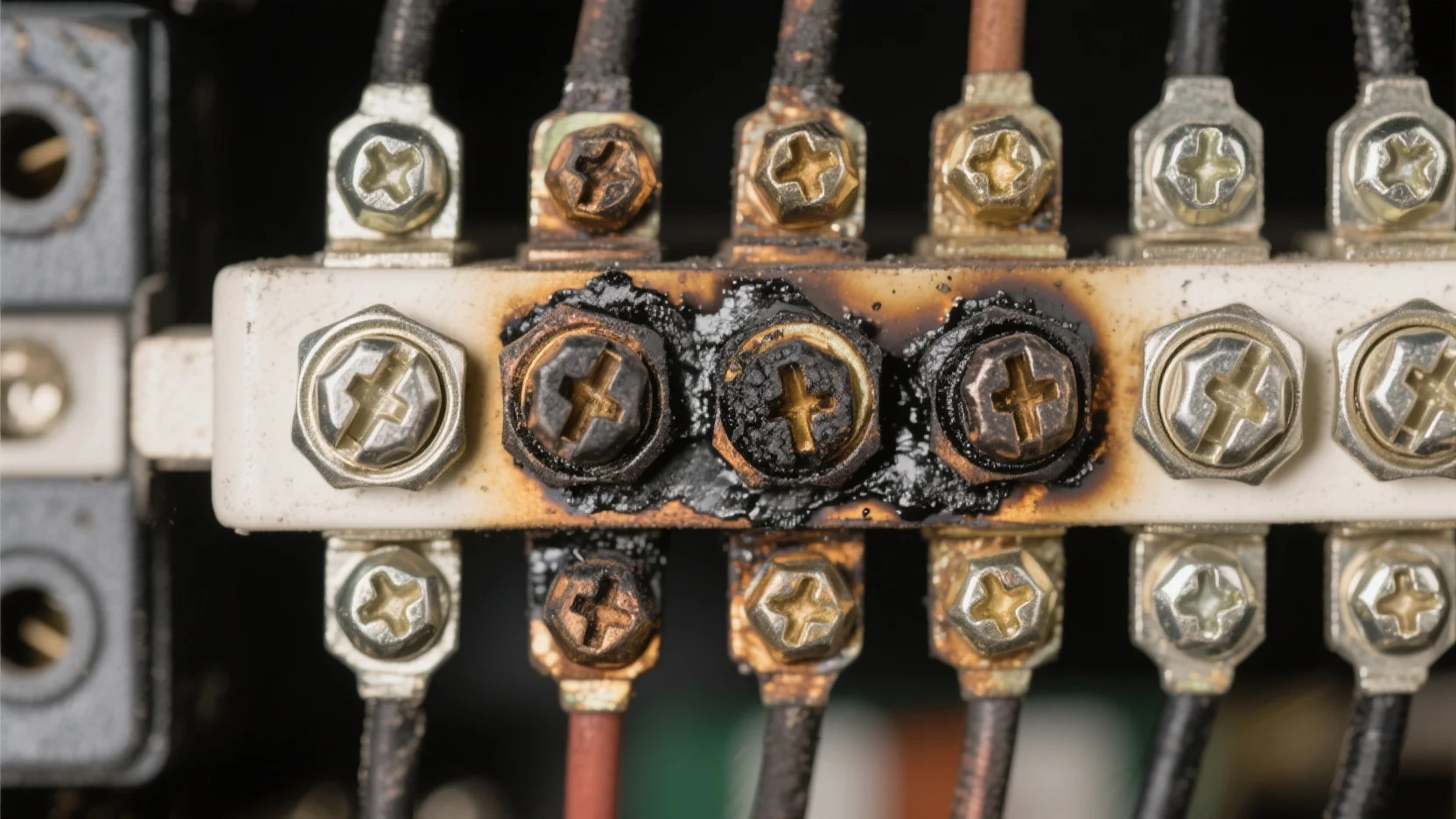

The input and output power terminals may become loose or oxidized, resulting in increased contact resistance and local high temperatures at the connection points. This is often accompanied by blackened or charred marks.

III. Systematic Diagnosis and Inspection Process

To ensure safety, the principle of "disconnect power first, then inspect" should be followed during the inspection.

Environmental and Installation Status Check

Make sure there is sufficient space for heat dissipation around the equipment (it is recommended to be no less than 10 centimeters), and the ventilation channels are not blocked.

Assess whether there are other high heat sources (such as frequency converters) in the control cabinet that could raise the ambient temperature.

Countermeasures: Clean the dust in the air ducts and consider installing auxiliary ventilation or cooling equipment.

Operation parameter diagnostic analysis

Use tools such as multimeters and oscilloscopes to measure the input voltage and output current of the equipment, verify whether they are within the rated range, and determine if there is an overload.

If the equipment is equipped with monitoring functions, access its internal temperature records to confirm whether it is approaching or has already triggered the alarm threshold.

Hardware status confirmation

Check the cooling fan. Manually move it to confirm whether it rotates smoothly without any jamming or abnormal noise.

Check whether the installation of the radiator and power devices is tight and whether the thermal grease is in good condition.

Carefully inspect all power connection terminals to ensure there is no looseness, burning, discoloration or scorch marks.

IV. Targeted Handling Solutions

Scenario of Overheating Core Handling Solutions

Normal overheating (<60℃) No special treatment is required, but a plan should be made to regularly clean dust and ensure smooth ventilation.

Poor heat dissipation system Replace faulty fans, thoroughly clean dust and oil stains; if the fans are normal, check the contact surface of the heat sink and reapply high-quality thermal grease.

Overload of load Immediately reduce the load to within the rated range, or replace the regulator with a matching (higher power) one. It is strictly prohibited for the equipment to operate under long-term overload.

Internal hardware failure Immediately execute emergency power-off and contact professional technicians for repair or replacement. It is strictly prohibited for non-professionals to disassemble the equipment by themselves.

V. Equipment Safety Maintenance Specifications

Standardized temperature measurement: To prevent burns and obtain accurate data, an infrared thermometer should be used during inspections to avoid direct contact with high-temperature surfaces by hand.

Preventive maintenance: Implementing quarterly or annual regular maintenance plans, which include dust removal, fan condition checks, terminal tightness checks, etc., can effectively prevent the vast majority of overheating faults caused by dust accumulation and loosening.

Be vigilant for syndrome signs: When fever is accompanied by a burnt smell, abnormal vibration or noise, it is a clear sign of a major malfunction (such as an internal short circuit). The machine must be shut down immediately for inspection and repair to prevent the accident from escalating.

Case Warning: During a routine inspection at a chemical plant, a maintenance worker noticed that the outer casing of a power regulator in the power adjustment cabinet was extremely hot and gave off a slight burnt smell. He immediately shut down the machine. After investigation, it was found that the cooling fan was stuck due to oil contamination and there was a serious accumulation of dust inside, which eventually led to the overheating and burning of the main thyristor. This incident, triggered by inadequate regular dust cleaning, was averted from developing into a potential short circuit fire through prompt handling.

It is a common phenomenon for the casing of a power regulator to be warm during normal operation, but if it is "too hot to touch", it is a dangerous signal that cannot be ignored. By using a systematic "environment - parameter - hardware" three-step troubleshooting method, accurately distinguishing between reasonable heating and pre-fault signs is one of the core skills for equipment managers to ensure the stable and safe operation of the production line.